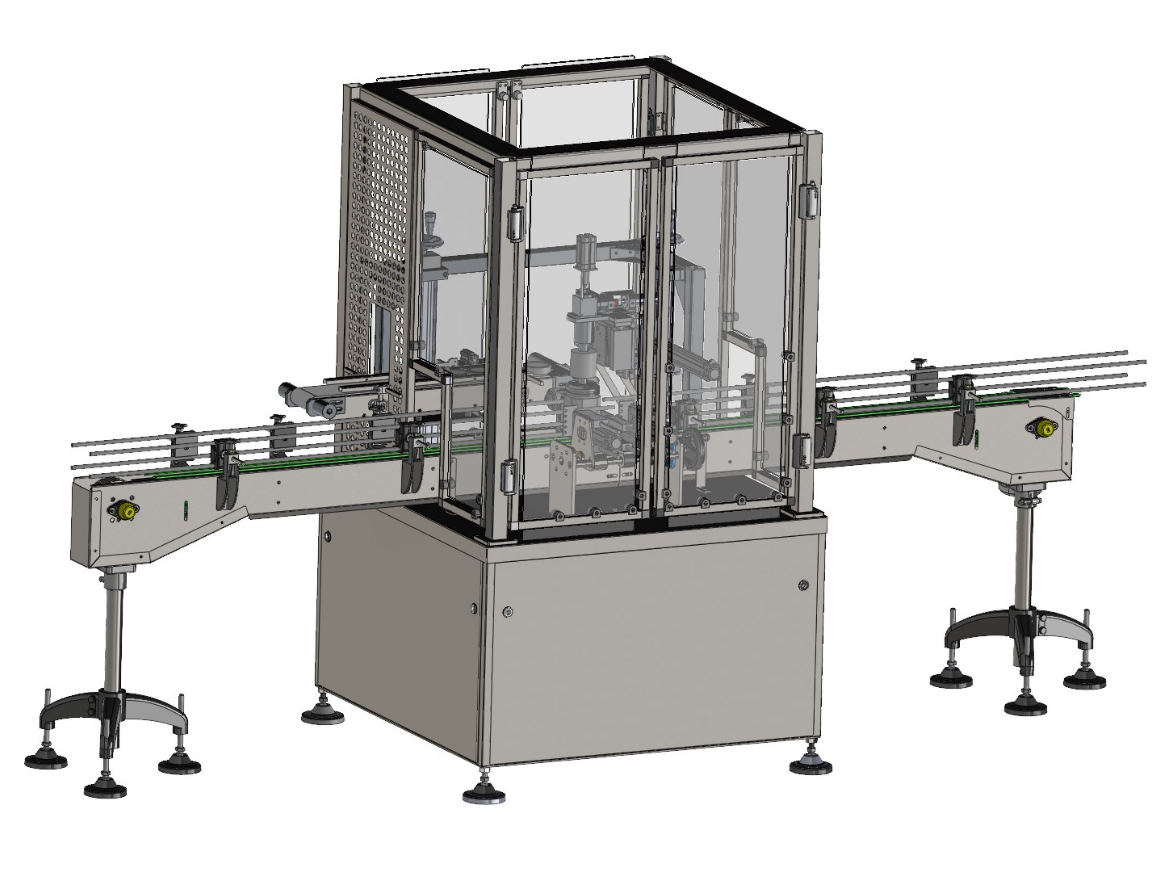

Capping machine for trigger pumps

Automatic capping line

The automatic capping line has been designed for those who need small production batches and many format changes as except for the capping head, the rest of the machine is adjustable and therefore without format change.

Caps or vases with particular shapes are an exception.

The automatic capping line is built in stainless steel and complete with all safety devices (doors and casings) according to CE standards. It is a linear machine, therefore the cap laying and capping take place on the conveyor belt.

The automatic capping line is equipped with a capping station with integrated pneumatic up / down and manual height adjustment using the appropriate handwheel to change the format.

The capping head is equipped with a hysteresis magnetic clutch to ensure maximum tightening precision. The friction is adjustable from 0.2 to 1.5 N / M.

The machine carries out the cap gripping operation from the appropriate location and immediately afterwards it closes.

The in-line automatic single-head capping machine is complete with a conveyor belt for incoming and outgoing jars.

This type of machine is also optimized for trigger capping.

- Stainless steel base on height-adjustable feet for easy online positioning

- Capping tower built in AISI 304 STAINLESS STEEL

- PICK & PLACE group – electro-pneumatic

- Capping head motorization with BRUSHLESS motor.

- Stroke of the vertical cam managed with a BRUSHLESS motor.

- Manual height adjustment.

- Electronic regulation of the machine speed by inverter

- Motorization of the belt with electronic speed management

- Electrical panel, in stainless steel and machine management with PLC and HM