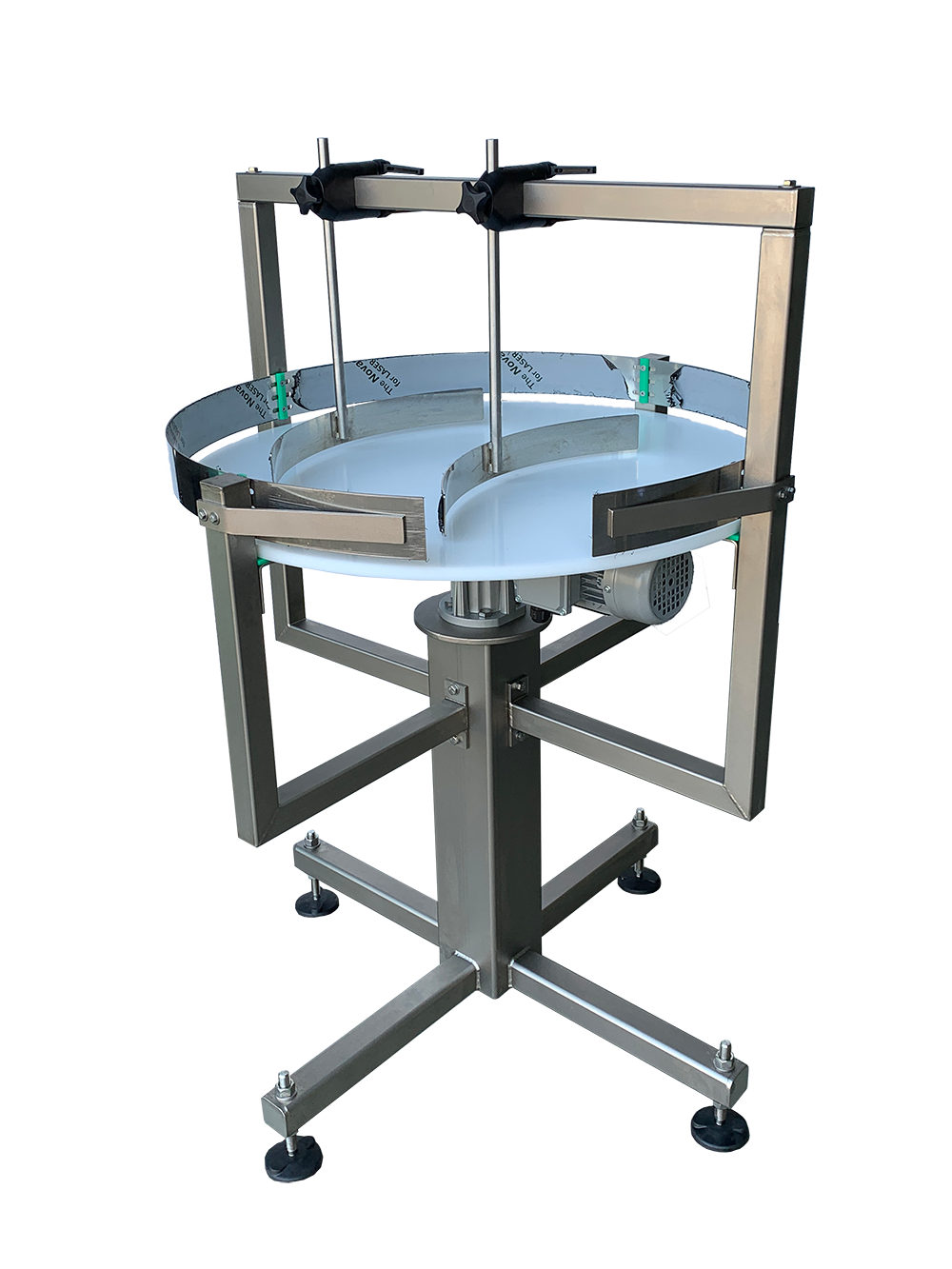

Automatic filling and capping table

Automatic filling and capping table

The automatic filling and capping table arises from the need of our customers to have a solution that allows the automatic filling and closing of jars and bottles. This guarantees a minimal and fast format change.

The machine is ideal for those who need maximum flexibility and quick format changes.

Given the great versatility and ease of use, it is used in the food, cosmetic and chemical sectors.

The automatic filling and capping table is built in stainless steel and non-toxic plastic parts, with very small sizes (Max, 1.5 × 1.5m) which allow it to be easily positioned within the production department.

The operator has the possibility to load a certain quantity of jars / bottles on the automatic filling and capping table, which varies according to the sizes of the latter. Once this is done, the cycle is completely automated and the machine conveys the jars / bottles to the filling station.

Once the dosage has been completed, the jar / bottle is released and moved under the capping head where the operator will have the task of manually positioning the cap in the correct way.

When also this activity is completed, the jar arrives in the capping station, where it is closed and then diverted onto a conveyor belt to perform the labeling and packaging operations.

Finally the jars / bottles are finally automatically moved to the accumulation area.

- Complete with all safety devices (doors and casing) according to CE standards

- Rotary type machine

- Jars / bottles conveyed outside using a special template

- Equipped with filling station with manual height adjustment

- Dosing Cylinder according to the available models

- Doser mounted in the lower part of the table at about 40cm from the ground

- Product load to be defined with the technical department according to the type of product to be filled

- Capping head complete with motor to screw the cap onto the bottle.